新(xin)聞中心

| 地址: | 河北省泊(bó)頭市道東街88号 |

| 電(diàn)話: | 0317-8185077 |

| 0317-8263980 | |

| 0317-8223128 | |

| 傳真: | 0317-8265584 |

| E-mail: | [email protected] |

| KCB300齒輪泵流量18m3/h做(zuo)潤滑油排油泵助(zhù)力四川成達 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 發布(bù)時間:2015-4-3 9:05:28 點擊次數: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

KCB300齒(chi)輪泵流量18m3/h,壓力0.36Mpa,吸(xī)入真空高度3米,效(xiao)率42%,口徑70,電機功率(lǜ)7.5KW KCB300齒輪圖片:

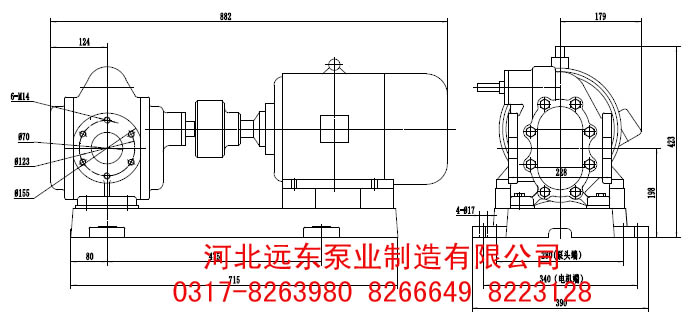

KCB300整機安(an)裝尺寸圖

KCB齒輪油(yóu)泵在輸油系統中(zhōng)可用作傳輸、增壓(yā)泵;KCB gear oil pump in the oil system can be used as a transport, booster pump; 在燃油系統中(zhōng)可用作輸送、加壓(ya)、噴射的燃油泵;In the fuel system can be used as a transport, pressure, jet fuel pump; 在(zài)一切工業領域中(zhong),均可作潤滑油泵(bèng)用。In all industrial areas, can be used as lubricating oil pump. KCB齒輪泵主要有(you)齒輪、軸、泵體、安全(quán)閥、軸端密封所組(zu)成。齒輪經熱處理(lǐ)✔️有較高的硬度和(hé)強度,與軸一同安(ān)裝在可更換的軸(zhóu)套内運轉。泵内全(quan)部零件的潤滑均(jun1)在泵工作時利用(yòng)👣輸出介質而自動(dong)達到。KCB gear pump are mainly gear, shaft, pump body, valve, shaft end seal. Gear after heat treatment with high hardness and strength, and shaft installed in the replaceable shaft sleeve. In all parts of the lubrication pump are pump work automatically to achieve using the output media. 泵内有設計(ji)合理的洩油和回(hui)油槽,是齒輪在工(gong)作中承受的扭🥵矩(jǔ)力最小,因此軸承(chéng)負荷小,磨損小,泵(beng)效率高。Pump is the drainage and back into the groove of reasonable design, is a gear in the work under the minimum torque force, so the bearing load is small, wear small, pump with high efficiency.

泵設有安(an)全閥作為超載保(bǎo)護,安全閥的全回(huí)流壓力為🏃♂️泵額定(dìng)排除壓力的1.5倍,也(ye)可在允許排出壓(ya)力範圍内根據實(shi)際需要另外調㊙️整(zhěng)。但注意本安全閥(fá)不能作減壓閥的(de)長期工🈲作,需要時(shi)📐可在管路上另行(háng)安裝。從主軸外伸(shen)端向泵看,為順時(shí)針💁旋轉。Pump is equipped with safety valve as overload protection, the total reflux pressure relief valve is rated pump out pressure of 1.5 times, also can allow discharge pressure range according to actual needs and adjust. But note that this cannot be a long-term work pressure reducing valve, relief valve can be installed in the piping shall be separately when necessary. To pump from the main shaft overhang end to see, for clockwise. KCB齒輪泵安(ān)裝順序: KCB gear pump installation order:

1、在安裝過(guò)程中,為防止雜物(wu)落入機器内,機組(zu)的所有㊙️孔眼均應(yīng)蓋好。1, during the installation process, so as to prevent debris into the machine, all perforation should cover of the unit. 2、在接好管路(lù)及确定電動機轉(zhuan)動方向後,再接上(shàng)聯軸✂️器,并👈再校核(hé)一遍軸的同心度(dù)。2, good on the line and determine the direction of motor rotation, and coupling is connected, check it again and shaft concentricity. 3、校正泵軸和電機(ji)軸的同心度,在聯(lián)軸大路外圓上,允(yǔn)許偏差0.1毫米;兩聯(lián)軸器平面的間隙(xi)應保證2~4毫米,(小泵(beng)取小值)間隙要均(jun)勻,允差0.3毫米。3, calibration of pump shaft and motor shaft concentricity, cylindrical, along the road in coupling allowable deviation of 0.1 mm;In the plane of the two coupling gap should guarantee 2 ~ 4 mm, small little pump (in value) clearance wants even, tolerance of 0.3 mm. 4、将機(ji)組放在埋有地腳(jiǎo)螺栓的基礎上,在(zai)底座與基🔴礎之間(jiān),用成🔞對的楔墊用(yong)校正用。4, put the unit in buried with anchor bolt, on the basis of between the base and foundation, with pairs of wedge cushion with correction. 5、為防止管(guan)線中雜物進入泵(bèng)内,對新安裝的管(guan)線,在泵膠應裝設(shè)♈過濾器,其有效截(jie)面應大于吸入管(guan)截面的2~3倍。5, in order to prevent debris into the pump in the pipeline, pipeline of new installation glue should be installed in the pump filters, the effective cross section should be greater than the suction pipe section 2 ~ 3 times. 6、松開聯(lian)軸大,用水平儀分(fen)别放在泵軸和底(di)座上,通過調整楔(xie)㊙️墊,校正機組水平(ping),适當擰緊地腳螺(luó)栓,以防走動。6, loose coupling, use level on the pump shaft and base, respectively, by adjusting the wedge cushion, correction unit level, tighten the anchor bolts, just in case. 7、在機(ji)組實際試運行2~3小(xiao)時後,作最後檢查(chá),如無不良現象,則(ze)認為安裝合格。 7, in the actual commissioning unit 2 ~ 3 hours later, a final inspection, if there is no negative phenomenon, is considered qualified installation.

|

傳真:0317-8265584 E-mail:[email protected]備案号:冀ICP05010751号(hao)-3

.jpg)